Manufacturer Cookware PTFE Cookware Ceramic Bakeware Coil Bakeware Spray Kitchen Electrics Home Gadgets

Retail & brands Cookware PTFE Cookware Ceramic Bakeware Coil Bakeware Spray SDA Kitchen Electrics SDA Home Gadgets Test methods Specials

Are you a retailer or brand provider?

This wayBakeware Coil

Our all-rounder for all applications

With this item ILAG offers an outstanding product for all baking applications that demand the highest quality and a long service life of a baking tin.

Properties

| Price segment | Best |

| Quality level for consumers | 5.5 / 5.5 |

| Base | Fluorpolymere / Resin |

| PFAS- and PTFE-free coatings | No |

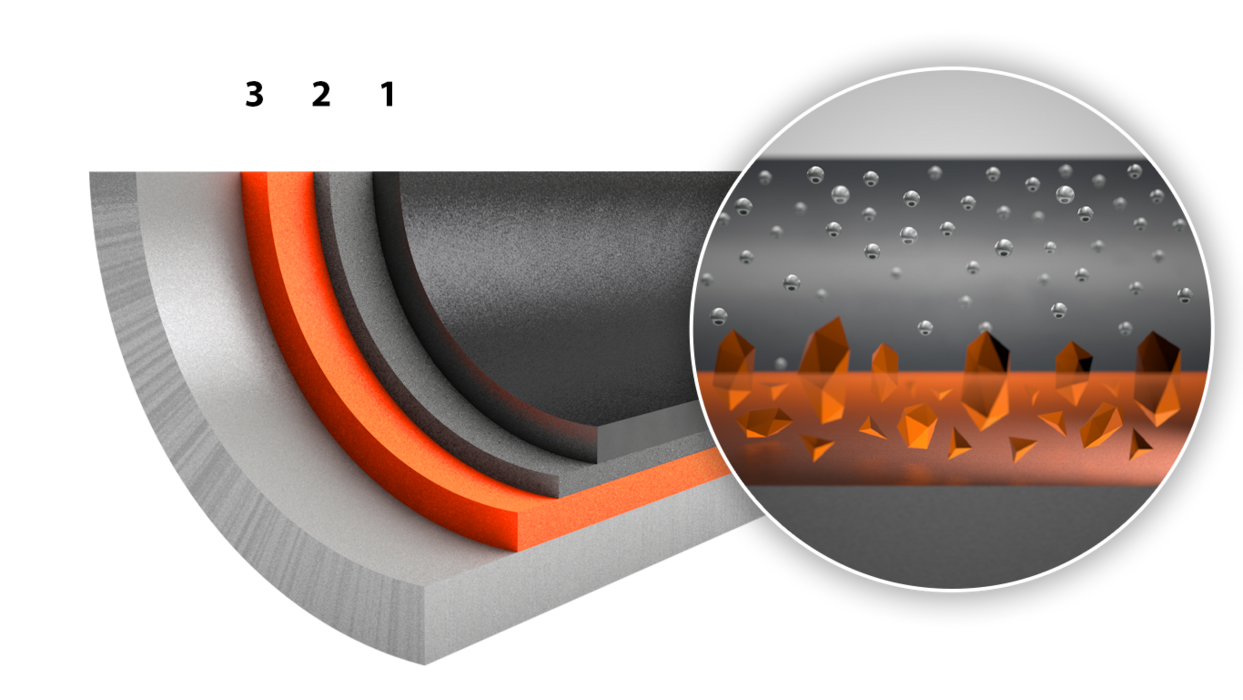

| Number of layers | 3 |

| Coating thickness | 22 - 25 µm / 0.87 - 0.98 mils |

| Curing temperature to approx | 380 °C / 716 °F |

| Service temperature | 230 °C / 446 °F |

| Coating type (base) | Solvent-based |

| Color variations |

muted colors |

Performance profile

| Abrasion | |

| Non-stick effect (ISO EN 13834) | |

| Staining resistance (chicken wings) | |

| Corrosion resistance (EU 10/2011) |

| Substrate | Pre-treatment | Suitability |

|---|---|---|

| aluminum | passivate free from chromium | |

| aluminized steel | passivate free from chromium | |

| ECCS | cleaning |

ILAFLON Triplus has an excellent non-stick effect and extraordinary stain resistance. Suitable for most demanding top level baking and roasting applications

ILAG basic test - Every non-stick coating must be tested for suitability for food contact by an independent institute after application. A declaration of no objection or a certificate of suitability is mandatory.

Procedure: There are various food contact standards that differ from country to country. The most commonly used and widely accepted are the following standards:

EEC – Regulation (EC) No. 1935/2004

USA – FDA CFR Title 21 Food and Drugs

DE – LFBG und BfR Standards

Do you have any further questions about our test methods? We will be happy to answer them.

ILAG basic test - This test is used to determine the coating thickness of the coating

Procedure: Each system has its own specification defined by the coating manufacturer. Manufacturers of cookware must meet the specifications for the dry film thickness (DFT!). Sometimes it is difficult to measure the DFT directly on the substrate during production, e.g. with cast aluminum, chrome steel and hard substrates. In such cases, the measurement must be carried out on a smooth aluminum sheet in order to obtain a value that is as close to reality as possible.

Assessment: The dry film thickness (DFT) is tested using electronic measurements at various points on the object or sheet.

Conclusion: As a rule of thumb, the higher the DFT, the more durable the coating.

Do you have any further questions about our test methods? We will be happy to answer them.

ILAG basic test (based on DIN EN ISO 2409) - This test is a simple way of testing the adhesion of a coating to the substrate.

Procedure: The procedure requires a cross pattern of 100 squares to be carved into the surface. This is done by making 11 parallel cuts approximately 5 cm long and 1-2 mm apart. These 11 cuts are then repeated across the existing lines. The cuts must penetrate the coating down to the substrate. A standardized adhesive tape (adhesive strength of 10 N/cm2) is then pressed onto the entire grid cut and then torn off again with a quick movement. This process must be repeated 5 times in succession - each time with a new adhesive tape.

Assessment: No square may be detached. To tighten the test, the test specimen can then be boiled in water for 15 minutes and the adhesive tear-off repeated.

Conclusion: If the coating does not peel off when the adhesive tape is torn off, the coating thickness has been applied sufficiently and the curing temperature has been regulated correctly.

Do you have any further questions about our test methods? We will be happy to answer them.

ILAG basic test - This basic test is carried out to detect cracks or open pores in the coating.

Procedure: The coating is viewed through a microscope at 30x magnification and examined for cracks.

Assessment: The coating is visually inspected and assessed for cracks and/or pores.

Conclusion: The integrity or impermeability of the coating prevents the cooked food from penetrating the substrate and thus prevents infiltration of the test object.

Do you have any further questions about our test methods? We will be happy to answer them.

ILAG test AA-068 (according to BS 7069:1988) - The test simulates the cleaning and scrubbing movements

Procedure: A predefined scouring pad (3M Scotch-Brite) is moved back and forth horizontally on the coating by machine under a certain load and with the addition of water and detergent. After a total of 200 individual strokes, with each pad side being changed once, a new scouring pad is clamped in. The process is repeated until 10% of the substrate is visible.

Assessment: The number of strokes is taken as an absolute value.

Conclusion: The longer the coating resists abrasion, the longer the life expectancy.

Do you have any further questions about our test methods? We will be happy to answer them.

ILAG test AA-079 - This test is used to check the non-stick effect in the baking pan

Procedure: After heating the fan oven to 180 °C [356 °F], pour the prepared butter cake batter into the ungreased baking tin. The baking time depends on the stick test. There must be no baking residue or crumbs sticking to the wooden stick. Remove the baking tin from the oven and leave to cool for 5 minutes. Turn the tin upside down and unmold the cake. After removal, wash the tin by hand with washing-up liquid and warm water. Repeat the baking process 10 times, cleaning in the dishwasher after the 4th and 8th cycle.

Assessment: After each baking process, a note is made of how the cake can be removed from the mold and how much residue is left in the baking mold. A defined factor is used to calculate both the demolding process and the cleanability.

Conclusion: Poor demolding indicates insufficient layer thickness or non-stick effect.

Do you have any further questions about our test methods? We will be happy to answer them.

ILAG test AA-062 - This test checks the stain resistance in the mold

Procedure: Season the chicken leg with Maggi (Aromat), pepper, paprika and rosemary needles. Preheat the fan oven, place the prepared leg in the baking dish, sprinkle with diced bacon and place in the oven. Cook the food at 220 °C [428 °F] for 15 minutes, turning once. Reduce the temperature to 180 °C [356 °F] and bake the chicken leg for a further 30 minutes. Once the roasting time has elapsed, use forks to lift the food out of the baking dish. The dish is cleaned by hand with a brush under warm water and dried. The test is repeated 15 times and after every 5th time the dish is cleaned in the dishwasher for one cycle.

Assessment: After each cycle, the adhesion, stain resistance and surface destruction are assessed. The result is calculated using a defined factor.

Conclusion: The better and thicker the coating, the less susceptible the mold is to non-stick and staining.

Do you have any further questions about our test methods? We will be happy to answer them.

ILAG test AA-080 (based on EN ISO 13834:2007) - This test is used to test the coating for stain resistance

Procedure: Place an unfrozen, raw piece of rump steak with no visible fat (weighing approx. 100g and 1 cm thick) in the middle of the baking dish. Place the dish with the steak in a fan oven preheated to 180 °C [356 °F]. After 1 hour of cooking time, remove the dish from the oven and check whether the meat is sticking to the coating. After removing the meat from the pan, pour off the meat juices and immerse the pan in water at 60 °C [140 °F]with a splash of washing-up liquid for a certain amount of time. Clean the mold with a natural sponge or the soft side of a household sponge. Then rinse with hot then cold water and dry. A total of 5 cycles are carried out before the final assessment.

Assessment: An assessment is determined for each cycle in accordance with a defined system. This assessment is carried out on a visual basis.

Conclusion: Both the non-stick effect, stain resistance and cleaning are covered by this test.

Do you have any further questions about our test methods? We will be happy to answer them.

ILAG test AA-138 - This test is used to test the coating for iron content

Procedure: The preparation of the sample wells for determining the iron content is very complex. A test formulation for determining the iron content, consisting of distilled water and citric acid, is filled into the coated wells. After the well has been heated in a glass beaker filled with water for 2 hours in boiling water with the lid closed, it can be carefully removed from the glass. It must be allowed to cool briefly before a predefined test strip is briefly immersed in the solution. After 20 seconds, the iron content in the coating can be read on a color scale. This test is carried out 3x2 hours and each time the wells must be filled with new Simulant solution.

Assessment: The result of the color scale is noted after each run. According to the instructions, the sum of the 1st and 2nd migrate must not exceed 7 times the limit value. The 3rd migrate must comply with the limit value. The limit value for iron is 40 mg/kg food simulant.

Conclusion: Too high an iron content in the coating is not permitted and the coating must not be placed on the market.

Do you have any further questions about our test methods? We will be happy to answer them.

ILAG test AA-061 - This test checks the coating for bubbles and infiltration

Procedure: A 2mm grid cut is made in advance on the floor and the inner wall and torn off 3 times with adhesive tape, and the convection oven is preheated to 200 °C. The test consists of 4 different solutions (meat stock, ketchup mixture, washing-up liquid solution and 5% acetic acid solution). Each test solution is boiled in the oven for 45 minutes and then poured out again before the new solution is poured in. After pouring out the last test solution, the mold is cleaned in the dishwasher and the grid cuts are torn off 3 times with adhesive tape. The complete cycle with the 4 solutions is carried out 4 times and takes a total of 5 days.

Assessment: The bubbles in the complete pan (base and wall) are measured after each cycle and the quantity of bubbles is noted. The result is calculated using a defined factor.

Conclusion: Blistering indicates a porous coating.

Do you have any further questions about our test methods? We will be happy to answer them.